Flush-mounted seats “Kompakt”

These seats are flush-mounted into the wall, and, if so requested, can be modelled to seamlessly merge with the wall so that they are scarcely visible at first glance. In their folded up resting position, these seats require no additional space at all, which makes them an ideal solution for easily crowded rooms such as elevator cabins.

But these seats have of course other installation opportunities besides elevator cabins. When your walls are built with the frame construction, for example, or if other space saving or optical requirements make it more desirable to opt for the flush built-in wall mounted fold down seat.

Among the many models You will find different measurements in width and depth, wall-casings should the walls be unable to support the construction, adapter frames to reduce installation depth, barely flammable or entirely flame-retardant models as well as casings in various colours or available in stainless steel, padded and upholstered or non-padded seats.

If there are any questions about

options or if you worry about the availability of options for you and

especially the possibility whether your walls are able to support our

products, please don’t hesitate to contact us. Any phone calls or

emails asking for more details are absolutely non-binding and we are

always looking forward to advise you.

Specifications and dimension sheets for download

Flush-mounted seats „Kompakt“

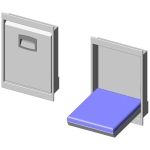

Flush built-in fold down seat

model: 007-13 (mild steel) to the details page

to the details pageFold down seat that’s flush-mounted into the wall. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position against the wall when not in use (but only with the padded seat options). Hard surfaced seating areas must not fold up on their own accord as there could be a risk of injury.

Intended for the use in elevator cabin but can be installed in other areas as well. The installation depth measures a mere 82 mm (3.2 inches). The screws used for the installation of the seat remain visible but if the wall is accessible from behind non-visible bolts can be installed as the installation is then executed from behind with screw nuts.

This seat matches the parameters of BS EN 81-70 (Accessibility to lifts for persons including persons with disability) if the seat is installed for the seating area to have a height of 48 to 52 cm (18.9 to 20,4 inches). The EN 81-70 is a part of the regulation DIN 18040 (barrier-free building – basis for planning), part one and two.

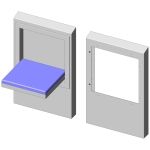

Flush built-in fold down seat

model: 007-24 (stainless steel) to the details page

to the details pageFold down seat that’s flush-mounted into the wall. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position against the wall when not in use (but only with the padded seat options). Hard surfaced seating areas must not fold up on their own accord as there could be a risk of injury.

Intended for the use in elevator cabin but can be installed in other areas as well. The installation depth measures a mere 82 mm (3.2 inches). The screws used for the installation of the seat remain invisible behind the masking frame.

This seat matches the parameters of BS EN 81-70 (Accessibility to lifts for persons including persons with disability) if the seat is installed for the seating area to have a height of 48 to 52 cm (18.9 to 20,4 inches). The EN 81-70 is a part of the regulation DIN 18040 (barrier-free building – basis for planning), part one and two.

Flush built-in fold down seat with black wall case

model: 007-24 (stainless steel) to the details page

to the details pageThe only difference between this folding seat and the standard 007-24 model is that it has a steel wall case in matte black instead of stainless steel.

The appearance when folded up is exactly the same as a folding seat made entirely of stainless steel. If you fold down the seat, you can see the black interior. Visually, this circumstance does not disturb at all, because the black upholstery and the black wall housing complement each other perfectly. Technically, there are also no differences or even disadvantages.

The big advantage lies in the manufacturing costs. With the black wall housing, this folding seat is around 17 percent cheaper.

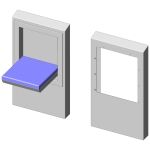

Flush built-in fold down seat, narrow

model: 007-52 (mild steel) to the details page

to the details pageFold down seat that’s flush-mounted into the wall. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position against the wall when not in use (but only with the padded seat options). Hard surfaced seating areas must not fold up on their own accord as there could be a risk of injury.

Intended for the use in elevator cabin but can be installed in other areas as well. The installation depth measures a mere 82 mm (3.2 inches). The screws used for the installation of the seat remain visible but if the wall is accessible from behind non-visible bolts can be installed as the installation is then executed from behind with screw nuts.

This seat is smaller than 007-13 and is thus suited in case of a lack of space but because of its more narrow build does not fulfil the requirements of the BS EN 81-70.

Flush built-in fold down seat, narrow

model: 007-53 (stainless steel) to the details page

to the details pageFold down seat that’s flush-mounted into the wall. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position against the wall when not in use (but only with the padded seat options). Hard surfaced seating areas must not fold up on their own accord as there could be a risk of injury.

Intended for the use in elevator cabin but can be installed in other areas as well. The installation depth measures a mere 82 mm (3.2 inches). The screws used for the installation of the seat remain invisible behind the masking frame.This seat is smaller than 007-24 and is thus suited in case of a lack of space but because of its more narrow build does not fulfil the requirements of the BS EN 81-70.

Flush built-in fold down seat, mini

model: 123-01 (stainless steel) to the details page

to the details pageFold down seat that’s flush-mounted into the wall. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position against the wall when not in use (but only with the padded seat options). Hard surfaced seating areas must not fold up on their own accord as there could be a risk of injury.

Intended for the use in elevator cabin but can be installed in other areas as well. The installation depth measures a mere 82 mm (3.2 inches). The screws used for the installation of the seat remain invisible behind the masking frame.

This seat is very narrow with a seating area that measures only 349 mm (about 13.7 inches) and is thus ideally suited for very limited spaces but because of its narrow build does not fulfil the requirements of the BS EN 81-70.

Flush built-in fold down seat, with covered in-wall installation

model: 007-69 (mild steel) to the details page

to the details pageFold down seat that’s built into the wall. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position against the wall when not in use (but only with the padded seat options). Hard surfaced seating areas must not fold up on their own accord as there could be a risk of injury.

The seat is mounted to a supporting structure, the wall frame of the seat is later cased. The seating area protrudes 19 mm (0.7 inches) from the wall to align the seating area and the casing. Other protrusions are possible.

The edges of the sheathing area surrounding the seat should be fittingly durable (especially if it is drywall).

Elevator seat

model: 123-12 (stainless steel) to the details page

to the details pageThis seat is made to replace damaged or broken seats of our competitors. Our competitor fused the wall recess into the wall of the elevator cabin and the folding seat was screwed into this recess. Our seat has no wall casing of its own but the wall recess does not have to be removed.

If the measurements of the wall recess in your elevator cabin fit the dimensions 384 x 340 x 63 mm (h x b x d) (15.1 x 13.4 x 2.4 inches) this seat can simply be swapped for the preinstalled, damaged seat.

Because of the pre-existing measurements the seating area is comparably small.

Accessory: Wall-casing for flush built-in fold down seat

model: 104-05 to the details page

to the details pageThis casing is best suited for the modification of fold down seats in elevator cabins.

The following models can be fitted with this application: 007-13 or 007-24.

With this casing it is not required to cut an opening and the forces are mostly channelled into the floor. Because of this an additional reinforcing of the wall-backside can be mostly or even entirely omitted.

The casing has a depth of only 85 mm (3.3 inches).

Accessory: Wall-casing for flush built-in fold down seat, narrow

model: 104-06 to the details page

to the details pageThis casing is best suited for the modification of fold down seats in elevator cabins.

The following models can be fitted with this application: 007-52 or 007-53.

With this casing it is not required to cut an opening and the forces are mostly channelled into the floor. Because of this an additional reinforcing of the wall-backside can be mostly or even entirely omitted.

The casing has a depth of only 85 mm (3.3 inches).

Accessory: Wall-casing for flush built-in fold down seat

model: 104-11 to the details page

to the details pageWith this casing formation-assembly of the seat models 007-13 and 007-24 is made possible. As such the casing is suitable to modify seats in elevator cabins should the cutting of the cabin wall is not desired.

The casing made of stainless steel has a depth of only 82 mm (3.2 inches), the casing made of mild steel has a depth of 87 mm (3.4 inches).

Accessory: Wall-casing for flush built-in fold down seat, narrow

model: 104-13 to the details page

to the details pageWith this casing formation-assembly of the seat models 007-52 and 007-53 is made possible. As such the casing is suitable to modify seats in elevator cabins should the cutting of the cabin wall is not desired.

The casing made of stainless steel has a depth of only 82 mm (3.2 inches), the casing made of mild steel has a depth of 87 mm (3.4 inches).

Accessory: Spacer frame for flush built-in fold down seat

model: 104-08 to the details page

to the details pageThis spacer frame reduces the installation depth of a fold down seat for about 30 mm (1.2 inches).

Applicable to the models 007-13 and 007-24.

Accessory: Spacer frame for flush built-in fold down seat, narrow

model: 104-09 to the details page

to the details pageThis spacer frame reduces the installation depth of a fold down seat for about 30 mm (1.2 inches).

Applicable to the models 007-52 and 007-53.

Accessory: Spacer frame for flush built-in fold down seat

model: 104-10 to the details page

to the details pageThis spacer frame reduces the installation depth of a fold down seat for about 45 mm (1.8 inches).

Applicable to the models 007-13 and 007-24.

Accessory: Spacer frame for flush built-in fold down seat, narrow

model: 104-14 to the details page

to the details pageThis spacer frame reduces the installation depth of a fold down seat for about 45 mm (1.8 inches).

Applicable to the models 007-52 and 007-53.

BLECH & TECH GmbH

Niederwaldstraße 4

79336 Herbolzheim, Germany

+49 (0) 76 43 / 33 38 95 - 0

+49 (0)76 43 / 33 38 95 - 11

nfblch-tchd

©2025 BLECH & TECH GmbH