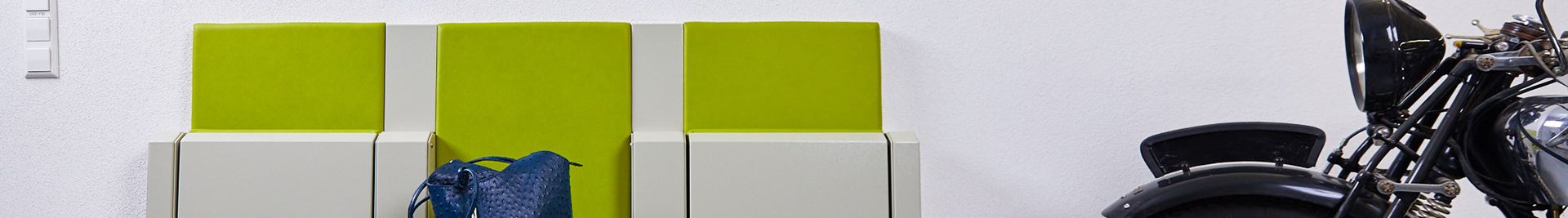

Fold down seats for drywall constructions

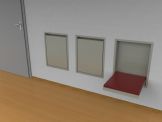

This mounting system creates sitting possibilities attached to dry wall partition systems.

Common plasterboard walls with metal-suppors are not fitted to have seating arrangements built into them or onto their frame work. Together with BST Rinklin, an expert for preventive fire protection technology, our company BLECH & TECH developed a mounting system which meets all requirements made by architects, technicians, but especially the eventual users.

A patent has been filed by BLECH & TECH for this mounting system.

Fire safety: In certain exit- and escape areas and routes loosely placed chairs are rightfully prohibited since they pose a dangerous obstacle if not a fire hazard. Seats that are built into the wall are the perfect solution for this problem. Additionally to the flame retardant upholstery, all compartements of the assembly system are made from metal and therefore not flammable. The non-visible installation frame comes with a fire proof casing which fulfils the same requirements as the rest of the wall.

The seat: When folded down the seat offers a, relative to other wall-in-built seats, big seat on which one can rest for a prolongued amount of time thanks to the comfort the larger seating area provides. The depth of the seat also makes it possible to sit parallel to the wall in order to communicate with seating neighbours or to combine the seat with a fold-down table.

The support construction: This is constructed from room-height support profiles between which a mounting frame is built. The amount of units that can be installed in combination can be freely varied. The grid measurement is 625 mm (24.6 inch), the depth of the profile can be set at either 75 mm (2.95 inch) (without fire safety casing and noise insulation), or 100 mm (3.94 inch) (with fire safety casing and noise insulation). UW-profiles are fixed to the top and the bottom of the mounting frame in order to be able to attach additional CW stands. The vertical support profiles can be tailored to fit the height of the room and have integrated CW profiles to be easily mounted on the planking.

The installation: The system units – vertical posts, mounting frame and the fold-down seat – are prepared to be ready for installation and can easily be integrated into wall systems with a stand construction corresponding to standard market norms. The wall cut out has to be installed into the room-side of the plasterboard and adjusted to the mounting frame. There are no requirements towards the cut-out edges as they will be covered by the casing of the fold-down seat and thus not visible once everything has been installed. The seat itself will be installed as the very last element, once plaster and paint work is finished.

Design: The fold-down seat is flush-mounted and integrates into the wall when folded up into its resting position. Because of this it can practically vanish and merge with the wall if designed to be rather inconspicuous or it can add colour and style through a more striking design or colour scheme. The seat can also be decorated with a logo or a pictogram. We offer a vast selection of colours for the casings of our seats additionally to a big variety of different upholstery styles. All other system components are out of sight, hidden behind the planking.

If there are any questions about options

or if you worry about the availability of options for you and

especially the possibility whether your walls are able to support our

products, please don’t hesitate to contact us. Any phone calls or

emails asking for more details are absolutely non-binding and we are

always looking forward to advise you.

Description of the elements and specifications for download

Components of the mounting system

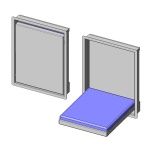

Fold down seat for drywall constructions

model: 166-01 to the details page

to the details pageFold down seat that’s flush-mounted into gypsum plasterboard walls. The seating area is brought into a resting position by the means of springs that will automatically bring the seat back into resting position when not in use.

This seat can be built into the mounting frame models 166-41 and 166-42. After the plaster and paint work on the selected wall has been completed the fold-down seat can be installed. It is important that the room-side planking is at least 25 mm (1 inch) thick (for example 2 x 12,5 mm | aka 2 x 0.5 inch).

When folded down the seat offers a, relative to other wall-in-built seats, big sitting area on which one can rest for a prolongued amount of time thanks to the comfort the large seat provides. The depth of the seat, about 450 mm (17.7 inch) also makes it possible to sit parallel to the wall in order to communicate with seating neighbours or to combine seats with a fold-down table.

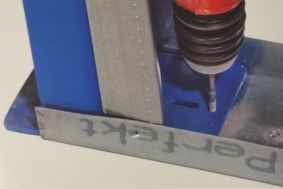

SPS-Post 75x50x4

model: 166-31 to the details page

to the details pageBST SPS-Post, type Perfect-Protect, with a builing depths of 75 mm (2.95 inch).

To be easily fitted into the construction area this post is available in variable multistages of which the lengths 3000 mm (118 inch) to 5000 mm (197 inch) can be readily delivered, special measurements can be arranged per request. Every design can be shortened up to 500 mm (20 inch). At the top end a 300 mm (12 inch) telescopic tube can be extended up to 50 mm (2 inch) to make fine adjustments. The integrated CW100-profile makes it easier to plank since the 4 mm (0.16 inch) thick steel pipe does not have to be fixed in place with screws. Both mounting plates can be fitted into the continuous UW100-profiles in the floor and the ceiling.

For the installation on floor and ceiling an installation kit will be included, consisting of 4 wood screws 6x60 and 4 nail anchors 6x30/5 for concrete.

This BST SPS-Post is protected as a utility model by BST Rinklin.

SPS-Post 100x50x4

model: 166-32 to the details page

to the details pageBST SPS-Post, type Perfect-Protect, with a builing depths of 100 mm (3.94 inch).

To be easily fitted into the construction area this post is available in variable multistages of which the lengths 3000 mm (118 inch) to 5000 mm (197 inch) can be readily delivered, special measurements can be arranged per request. Every design can be shortened up to 500 mm (20 inch). At the top end a 300 mm (12 inch) telescopic tube can be extended up to 50 mm (2 inch) to make fine adjustments. The integrated CW100-profile makes it easier to plank since the 4 mm (0.16 inch) thick steel pipe does not have to be fixed in place with screws. Both mounting plates can be fitted into the continuous UW100-profiles in the floor and the ceiling.For the installation on floor and ceiling an installation kit will be included, consisting of 4 wood screws 6x60 and 4 nail anchors 6x30/5 for concrete.

This BST SPS-Post is protected as a utility model by BST Rinklin.

SPS-Mounting frame 75

model: 166-41 to the details page

to the details pageMounting frame with a depth of 75 mm (2.95 inch), without fire safety casing and noise insullation.

At the top and the bottom horizontal UW-profiles are situated whereas on the sides UD-profiles are arranged onto which the planking can be attached via screws. In the UW-profiles additional CW-profiles can be placed. On the mounting frame is a marking saying “OKFF +1,00 m” (39,4 inch) to offer an easy method of reaching a seating height of 480 mm (18.9 inch). Differing sitting heights can be arranged per request. In order to install the mounting frame to the vertical posts 8 drilling screws are included.

The two vertical posts with integrated CW-profile shown in the picture to the right are not included in the scope of delivery of the mounting frame.

SPS-Mounting frame 100

model: 166-42 to the details page

to the details pageMounting frame with a depth of 100 mm (3.94 inch), including fire safety casing and noise insullation.

At the top and the bottom horizontal UW-profiles are situated whereas on the sides UD-profiles are arranged onto which the planking can be attached via screws. In the UW-profiles additional CW-profiles can be placed. On the mounting frame is a marking saying “OKFF +1,00 m” (39,4 inch) to offer an easy method of reaching a seating height of 480 mm (18.9 inch). Differing sitting heights can be arranged per request. In order to install the mounting frame to the vertical posts 8 drilling screws are included.

The two vertical posts with integrated CW-profile shown in the picture to the right are not included in the scope of delivery of the mounting frame.

BLECH & TECH GmbH

Niederwaldstraße 4

79336 Herbolzheim, Germany

+49 (0) 76 43 / 33 38 95 - 0

+49 (0)76 43 / 33 38 95 - 11

nfblch-tchd

©2026 BLECH & TECH GmbH